In 1967, Chevrolet was

busy promoting their new pony car,  the Camaro, and part of the promotional efforts included

racing the Camaro in the SCCA Trans-Am series. the Camaro, and part of the promotional efforts included

racing the Camaro in the SCCA Trans-Am series.  In order to make the

Camaro competitive, Chevrolet introduced the In order to make the

Camaro competitive, Chevrolet introduced the  Z/28 option package which

included among Z/28 option package which

included among other things, a special 302 cubic inch small block. The engine size other things, a special 302 cubic inch small block. The engine size was a result of the

SCCA's 305 cubic inch was a result of the

SCCA's 305 cubic inch  displacement limit in the Trans-Am series at the time. The 302 turned out to be

one of Chevrolet's finest displacement limit in the Trans-Am series at the time. The 302 turned out to be

one of Chevrolet's finest  small block offerings, and the engine stood in stark contrast to the ever

increasing small block offerings, and the engine stood in stark contrast to the ever

increasing  size of the big blocks used in the muscle cars of the day. size of the big blocks used in the muscle cars of the day.

To

arrive at the SCCA legal 302 cubic inches, Chevrolet used a 4.00" bore To

arrive at the SCCA legal 302 cubic inches, Chevrolet used a 4.00" bore  and a 3.00" stroke

resulting in a very oversquare (the bore is larger than the stroke) combination. and a 3.00" stroke

resulting in a very oversquare (the bore is larger than the stroke) combination.  In overly simple terms and

ignoring such important design factors such as bore / stroke ratio, In overly simple terms and

ignoring such important design factors such as bore / stroke ratio,  an engine with a short

stroke has the ability to rev higher due to slower piston speeds. an engine with a short

stroke has the ability to rev higher due to slower piston speeds.  As an example, think of

two engines, A and R. Engine A has a stroke of 3.00", As an example, think of

two engines, A and R. Engine A has a stroke of 3.00",  while engine B has a

stroke of 4.00". If both engines are turning at a speed of 4000 rpm, while engine B has a

stroke of 4.00". If both engines are turning at a speed of 4000 rpm,  the pistons of engine A

have less distance to travel than those of engine B. the pistons of engine A

have less distance to travel than those of engine B.  Since both engines are

turning at the same rpm, the pistons of engine R have to cover more distance in Since both engines are

turning at the same rpm, the pistons of engine R have to cover more distance in  the same amount of time as

the pistons of engine A, resulting in higher piston speeds. the same amount of time as

the pistons of engine A, resulting in higher piston speeds. Short stroke engines,

therefore, can run higher rpm with greater reliability and less stress on the Short stroke engines,

therefore, can run higher rpm with greater reliability and less stress on the reciprocating assembly.

This is the approach Chevrolet took when designing the 302 for SCCA competition. reciprocating assembly.

This is the approach Chevrolet took when designing the 302 for SCCA competition.

The

blocks used in 1967 were casting number 3892657. The

blocks used in 1967 were casting number 3892657.  These small journal blocks

were also used for 327 and 350 cubic inch engines as well (all three engines used a

4.00" bore). These small journal blocks

were also used for 327 and 350 cubic inch engines as well (all three engines used a

4.00" bore).  1968 models used block casting number 3914678 and featured the new style large

journals. 1968 models used block casting number 3914678 and featured the new style large

journals. The 1968 block was also used for the 327/210 hp and 350 295 hp SS engines. The 1968 block was also used for the 327/210 hp and 350 295 hp SS engines. The blocks used in 1969

featured thicker webbing around the mains and used nodular iron 4 bolt caps. The blocks used in 1969

featured thicker webbing around the mains and used nodular iron 4 bolt caps.  A common misconception is

that 1967 and 1968 302's A common misconception is

that 1967 and 1968 302's  were 4 bolt blocks, while actually were 4 bolt blocks, while actually  the only engine to use 4

bolt main caps was the 1969 version. the only engine to use 4

bolt main caps was the 1969 version.

The

crankshafts used were forged steel, tufftrided pieces in all three years. The

crankshafts used were forged steel, tufftrided pieces in all three years.  1967 models used a small

journal crank with 2.000" rod journals and 2.299" main journals. 1967 models used a small

journal crank with 2.000" rod journals and 2.299" main journals.  1968 and 1969 models used

a large journal crank featuring 2.100" rod journals and 2.449" main journals. 1968 and 1969 models used

a large journal crank featuring 2.100" rod journals and 2.449" main journals.  The forged cranks were

deemed necessary due to the high rpm the 302s were expected to see. The forged cranks were

deemed necessary due to the high rpm the 302s were expected to see.    The connecting rods varied considerably from year to year. The connecting rods varied considerably from year to year.  1967 models used what was

the standard small journal 1967 models used what was

the standard small journal rod of the time with a pressed in wrist pin and 5/16" rod bolts. rod of the time with a pressed in wrist pin and 5/16" rod bolts.  Two styles of rods were

used in 1968, the first being a Two styles of rods were

used in 1968, the first being a  strong large journal rod using a pressed pin and larger

3/8" rod bolts. strong large journal rod using a pressed pin and larger

3/8" rod bolts.  Middle production 1968 rods were changed to a floating wrist pin design. Middle production 1968 rods were changed to a floating wrist pin design.

Both early and late style 1968 rods were shot peened (a stress relieving process) Both early and late style 1968 rods were shot peened (a stress relieving process) at the factory. 1969

engines continued to use the late 1968 style floating wrist pin rod. at the factory. 1969

engines continued to use the late 1968 style floating wrist pin rod.

All

302s used a special baffled oil pan (the baffles prevented the All

302s used a special baffled oil pan (the baffles prevented the  uncovering of the oil pump

pickup as a result of the g-forces generated during acceleration, braking uncovering of the oil pump

pickup as a result of the g-forces generated during acceleration, braking  and cornering) and a high

pressure oil pump. and cornering) and a high

pressure oil pump.

All

1967 and early production 1968 302s used a All

1967 and early production 1968 302s used a  pressed pin design forged

aluminum piston with an 11.0: 1 compression ratio. Late 1968 production pressed pin design forged

aluminum piston with an 11.0: 1 compression ratio. Late 1968 production pistons switched to a

floating pin design. The 1967 and early 1968 pistons used a dome design taken from the

327/350 hp engine, pistons switched to a

floating pin design. The 1967 and early 1968 pistons used a dome design taken from the

327/350 hp engine,  and featured two individual valve reliefs in the dome. Late 1968 piston design

has a long notch-type and featured two individual valve reliefs in the dome. Late 1968 piston design

has a long notch-type valve relief cut across the entire dome. 1969 models featured a new 11.0:1

compression impact valve relief cut across the entire dome. 1969 models featured a new 11.0:1

compression impact extruded piston with slipper skirts and a floating wrist pin. The dome design

was the same as the late 1968 pistons. extruded piston with slipper skirts and a floating wrist pin. The dome design

was the same as the late 1968 pistons.

Cylinder

heads used on the 302s can be a bit confusing. Cylinder

heads used on the 302s can be a bit confusing.  In 1967, two different

cylinder head castings were used on the 302, 3917291 and 3890462. Both heads used In 1967, two different

cylinder head castings were used on the 302, 3917291 and 3890462. Both heads used  2.02" intake and

1.60" exhaust valves. The confusion arises from the fact that the 3890462 casting 2.02" intake and

1.60" exhaust valves. The confusion arises from the fact that the 3890462 casting was also produced using

smaller 1.94" intake and 1.50" exhaust valves, although this head was never was also produced using

smaller 1.94" intake and 1.50" exhaust valves, although this head was never used on the 302. 1968

heads were also produced using casting number 3917291, but 1968 heads included used on the 302. 1968

heads were also produced using casting number 3917291, but 1968 heads included  a provision for a water

temperature sensor not included on 1967 heads. Valve sizes were again 2.02" and

1.60" a provision for a water

temperature sensor not included on 1967 heads. Valve sizes were again 2.02" and

1.60" intake and exhaust respectively. To further complicate matters a small valve

version of the 3917291 head intake and exhaust respectively. To further complicate matters a small valve

version of the 3917291 head  using 1.94" and 1.50" intakes and exhausts was used on the SS 350

engines in 1968. So far that's two using 1.94" and 1.50" intakes and exhausts was used on the SS 350

engines in 1968. So far that's two  different versions of the 3890462 cylinder head and

three versions of the 3917291 cylinder head! different versions of the 3890462 cylinder head and

three versions of the 3917291 cylinder head! Both castings had the

familiar "double hump" machined pad located on each end of the head. Both castings had the

familiar "double hump" machined pad located on each end of the head.  1969 engines used head

casting number 3927186 and featured the large 1969 engines used head

casting number 3927186 and featured the large  2.02" intake and

1.60" exhaust valves of the earlier heads. 1969 heads also have holes drilled and 2.02" intake and

1.60" exhaust valves of the earlier heads. 1969 heads also have holes drilled and  tapped in the ends due to

a change in the alternator mounting method. tapped in the ends due to

a change in the alternator mounting method.  All of the 302 cylinder

heads, regardless of casting number, had the same characteristics. All of the 302 cylinder

heads, regardless of casting number, had the same characteristics.  Large port volumes and

large valves were used to facilitate breathing at high rpm, at the expense of low to

midrange efficiency. Large port volumes and

large valves were used to facilitate breathing at high rpm, at the expense of low to

midrange efficiency.

Fortunately,

identifying the camshafts used in the 302s is much more straightforward Fortunately,

identifying the camshafts used in the 302s is much more straightforward than the identifying the

cylinder heads. All three year model 302s used the famed solid than the identifying the

cylinder heads. All three year model 302s used the famed solid  lifter "30/30"

camshaft, so named because of the .030" intake and .030" exhaust valve lash

adjustments. lifter "30/30"

camshaft, so named because of the .030" intake and .030" exhaust valve lash

adjustments.  This camshaft was also used in the 1964 and 1965 special high performance and

fuel injected 327's This camshaft was also used in the 1964 and 1965 special high performance and

fuel injected 327's installed in the Corvette. Again, due to the high rpm nature of the 302,

a solid lifter camshaft was chosen. installed in the Corvette. Again, due to the high rpm nature of the 302,

a solid lifter camshaft was chosen.  Solid (or mechanical) lifters require maintenance more

often than hydraulic lifters, but are more reliable Solid (or mechanical) lifters require maintenance more

often than hydraulic lifters, but are more reliable at high engine speeds

than the hydraulic lifters. Hydraulic lifters tend to "pump-up" at higher rpm, at high engine speeds

than the hydraulic lifters. Hydraulic lifters tend to "pump-up" at higher rpm,  which leads to valve

float. This is not as much of a problem today due to the advances in which leads to valve

float. This is not as much of a problem today due to the advances in valvetrain design, but

was quite a concern in the mid-'60s. valvetrain design, but

was quite a concern in the mid-'60s.  Specifications for the cam are .452" intake and

.455" exhaust lift, 229 degrees intake duration and Specifications for the cam are .452" intake and

.455" exhaust lift, 229 degrees intake duration and 237 degrees exhaust

duration (both measured at .050" tappet lift) and 78 degrees of overlap (at 0 lift). 237 degrees exhaust

duration (both measured at .050" tappet lift) and 78 degrees of overlap (at 0 lift).

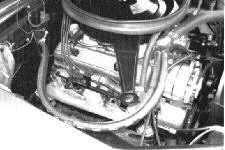

Chevrolet

needed an appropriate intake manifold to take Chevrolet

needed an appropriate intake manifold to take  advantage of the other

high performance engine pieces, and they settled on a single four barrel advantage of the other

high performance engine pieces, and they settled on a single four barrel  aluminum high rise design.

The basic design of the manifold remained unchanged from 1967 to 1969 aluminum high rise design.

The basic design of the manifold remained unchanged from 1967 to 1969  although two different

casting numbers were used. 1967 and 1968 engines used casting number 3917610, although two different

casting numbers were used. 1967 and 1968 engines used casting number 3917610,  and the intake featured

the thermostat hole located off-center toward the drivers side of the car. and the intake featured

the thermostat hole located off-center toward the drivers side of the car.  The engine temperature

sensor on 1967 models was located in a drilled and tapped hole next to the The engine temperature

sensor on 1967 models was located in a drilled and tapped hole next to the thermostat opening. On

1968 intakes, this hole is plugged due to the relocation of the sensor to the head. thermostat opening. On

1968 intakes, this hole is plugged due to the relocation of the sensor to the head. 1969 intakes, casting

number 3932472, centered the thermostat 1969 intakes, casting

number 3932472, centered the thermostat  hole and are otherwise unchanged from the earlier

intake. hole and are otherwise unchanged from the earlier

intake.  As

an over the counter option in 1969 (available through the parts department, never

installed As

an over the counter option in 1969 (available through the parts department, never

installed  by the factory), the Z/28 buyer could order a dual four barrel aluminum cross ram

intake manifold by the factory), the Z/28 buyer could order a dual four barrel aluminum cross ram

intake manifold  (casting number 3940077). This intake was designed so that longer (casting number 3940077). This intake was designed so that longer intake runners and two

carburetors could be used while fitting under the stock hood. In 1969, intake runners and two

carburetors could be used while fitting under the stock hood. In 1969,  the intake came with a

special ZL2 cowl induction hood and air cleaner. the intake came with a

special ZL2 cowl induction hood and air cleaner. This intake performed

poorly on the street, but when used on high rpm competition engines (the engine was This intake performed

poorly on the street, but when used on high rpm competition engines (the engine was designed for SCCA racing,

after all) really came into it's element. designed for SCCA racing,

after all) really came into it's element.

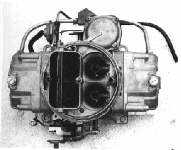

Holley 800 cfm dual-feed carburetors were used on all 302s,

Holley 800 cfm dual-feed carburetors were used on all 302s,  although list numbers

differed somewhat on 1967 models. Cars built at the Norwood, Ohio assembly plant although list numbers

differed somewhat on 1967 models. Cars built at the Norwood, Ohio assembly plant  used list number 3910

carburetors only, while cars built at the Los used list number 3910

carburetors only, while cars built at the Los Angeles plant used list

number 3910 and list number 3911, the latter being used Angeles plant used list

number 3910 and list number 3911, the latter being used on cars equipped with an

AIR (Air Injection Reactor) emissions system. on cars equipped with an

AIR (Air Injection Reactor) emissions system.  California laws mandated

that any new car sold within the state must be California laws mandated

that any new car sold within the state must be  equipped with an emissions

control system, thus the difference in carburetors. equipped with an emissions

control system, thus the difference in carburetors.

All 1968 and 1969 302's used All 1968 and 1969 302's used  an AIR system thereby allowing the an AIR system thereby allowing the use of the same

carburetor (list number use of the same

carburetor (list number 4053) regardless of assembly plant or car destination. 4053) regardless of assembly plant or car destination.  The use of Holley

carburetors on the 302's followed a Chevrolet tradition of using Holleys on their high The use of Holley

carburetors on the 302's followed a Chevrolet tradition of using Holleys on their high performance engines. In

fact, the 4053 carburetor also saw duty performance engines. In

fact, the 4053 carburetor also saw duty on the 396/375 hp big blocks of 1968. Holleys are still

used on the on the 396/375 hp big blocks of 1968. Holleys are still

used on the  vast majority of carbureted competition engines and offer a high vast majority of carbureted competition engines and offer a high  degree of adjustability,

performance and reliability. degree of adjustability,

performance and reliability.

The

exhaust manifolds used on 302s in 1967 and 1968 were little more than the The

exhaust manifolds used on 302s in 1967 and 1968 were little more than the  standard "log"

type found on most small block equipped passenger cars. The only major difference between standard "log"

type found on most small block equipped passenger cars. The only major difference between  years is non-AIR equipped

1967 versions have no provisions for smog tubes. Chevy must have felt that years is non-AIR equipped

1967 versions have no provisions for smog tubes. Chevy must have felt that the majority of Z/28

owners would bolt on their own headers if so desired. In 1969, Chevrolet made the majority of Z/28

owners would bolt on their own headers if so desired. In 1969, Chevrolet made  available a tube header

option for the 302 engine (when this option was ordered, the engine in the car available a tube header

option for the 302 engine (when this option was ordered, the engine in the car  came equipped with exhaust

manifolds while the headers were shipped in the trunk of the car) along with a came equipped with exhaust

manifolds while the headers were shipped in the trunk of the car) along with a low restriction chambered

exhaust system. The chambered exhaust was discontinued in May of 1969 low restriction chambered

exhaust system. The chambered exhaust was discontinued in May of 1969 due to problems with

passing noise laws. due to problems with

passing noise laws.

All

302s used a standard single point type distributor, All

302s used a standard single point type distributor,  although the advance

curves although the advance

curves  were

optimized for the needs of the 302. were

optimized for the needs of the 302.

What

all of these various pieces added up to was a healthy small block rated very What

all of these various pieces added up to was a healthy small block rated very  conservatively at 290

horsepower at 5800 rpm and 290 ft. lbs. of torque at 4200 rpm. Rumor has it, conservatively at 290

horsepower at 5800 rpm and 290 ft. lbs. of torque at 4200 rpm. Rumor has it,  however, that the same

engine produced 350 horsepower at 7000 rpm on the dynamometer! however, that the same

engine produced 350 horsepower at 7000 rpm on the dynamometer!  Why would Chevy underrate

the engine? Certainly insurance reasons come to mind, along with the Why would Chevy underrate

the engine? Certainly insurance reasons come to mind, along with the  desire to understate what

the engine was capable of lest the various racing sanctioning bodies penalize desire to understate what

the engine was capable of lest the various racing sanctioning bodies penalize the teams that chose to

run the Z/28 in competition. the teams that chose to

run the Z/28 in competition.

Road

tests of the day praised the engine that Road

tests of the day praised the engine that Chevy put together. While most testers found the lack

of "bottom end" power a nuisance, Chevy put together. While most testers found the lack

of "bottom end" power a nuisance, the 302 more than made up

for that shortcoming with a very strong the 302 more than made up

for that shortcoming with a very strong  top end rush. One tester likened the pull of the Z/28 in

the upper rpm range as being similar to a top end rush. One tester likened the pull of the Z/28 in

the upper rpm range as being similar to a  426 Hemi! That's high praise indeed for an engine with

two-thirds the displacement. 426 Hemi! That's high praise indeed for an engine with

two-thirds the displacement.  Quarter mile times were in the low to mid 14-second bracket, depending upon the

conditions the test Quarter mile times were in the low to mid 14-second bracket, depending upon the

conditions the test  was performed under. Modified 302s used in Trans-Am racing generated in the

neighborhood of 450 was performed under. Modified 302s used in Trans-Am racing generated in the

neighborhood of 450 horsepower, which is an amazing amount of power from 302 cubic inches with

enough horsepower, which is an amazing amount of power from 302 cubic inches with

enough reliability to win SCCA championships in 1968 and 1969.

reliability to win SCCA championships in 1968 and 1969.

The 302

powered Z/28 was very successful in both NHRA drag racing and SCCA Trans-Am racing The 302

powered Z/28 was very successful in both NHRA drag racing and SCCA Trans-Am racing from 1967 to 1969. The

Penske team with Mark Donahue dominated the Trans-Am series in 1968 and from 1967 to 1969. The

Penske team with Mark Donahue dominated the Trans-Am series in 1968 and  1969 (winning

manufacturer's championships for Chevrolet), while in 1968 Dave Strickler won 1969 (winning

manufacturer's championships for Chevrolet), while in 1968 Dave Strickler won  the IHRA Super Stock world

title in a 302 powered Z/28. That the engine and thus the car was so the IHRA Super Stock world

title in a 302 powered Z/28. That the engine and thus the car was so successful so soon after

its release is a testament to the effort that went into the project by successful so soon after

its release is a testament to the effort that went into the project by  Chevy's engineers. It is,

without a doubt, one of the all-time great small blocks produced by Chevrolet. Chevy's engineers. It is,

without a doubt, one of the all-time great small blocks produced by Chevrolet.

|